How to Update Your Gravel Roof

Is it time to update your gravel roof? It might be! Gravel roofs are long-lasting and UV and impact-resistant, making them great choices for areas prone to hail and rough weather. However, they do need regular inspection and maintenance to last longer and prevent water leaks.

What Is a Gravel Roof?

Do you have a gravel roof or a ballast roof? Although gravel roofs may look the same at a distance, there are actually two different kinds of roofs with rock on them.

Gravel roofs are typically tar roofs or built up roofs (BURs), the gravel is a final protective cover after many layers of roofing felt—often made of fiberglass—and hot-applied asphalt. BURs apply hot gravel so it sticks to the asphalt. The gravel protects from UV rays and extreme weather like hail, along with foot traffic.

Ballast roofs are usually a single-ply roof. This roof system may consist of a vapor barrier, foam insulation and a thin rubber membrane. The membrane of the roofing system is not fully adhered to the roof deck, so the gravel acts as ballast or weight to hold the roofing system down, while also providing weather and impact protection. The rock is usually larger in size than a true gravel roof. In this roof system the rock is an important part of the overall engineering of the building and each roof must be carefully addressed by experts in the field before the rock can be removed for repairs or replacement.

Limitations of a Gravel Roof

While gravel roofs are common and durable, there are challenges to them. The gravel layer means that damage to the layer below is not always visible, which can lead to leaks and water damage that are difficult to source. The gravel also means that when it comes time for a new roof the expense and hassle of removing and disposing of the old gravel roof can be daunting.

Inspecting Your Gravel Roof

Your staff or a contractor should inspect your roof at least once a year. Inspections following extreme weather events are also a good idea. As part of your checklist, make sure you do the following:

- Identify any new owner/tenant improvements since the last inspection, and check that flashings and tie-ins were done properly.

- Look for areas where the gravel cover is missing or is thin; these are more prone to damage.

- Check for poor drainage from coolers, condensers and air conditioning units. Install overflow control and piping as needed.

- Clean leaves, dirt and debris from valleys and waterways.

- Inspect drains, scuppers, overflows, gutters and downspouts for blockage. Clean as needed. Install or replace proper baskets and strainers as needed.

- Assess all roof penetrations, vents, pipes and flashings for cracks, and reseal as needed using Western Colloid Elastic Cement.

- Check all curbs, base flashings and wall terminations, and reseal as necessary with Western Colloid Elastic Cement.

Depending on the amount of any damage, your staff may be able to make repairs themselves, or you may have to hire a qualified contractor. In either case, make sure your roof inspections are documented, including photos, so that the roof condition is on record, in case of damage by other trades throughout the year.

Replacing Your Gravel Roof

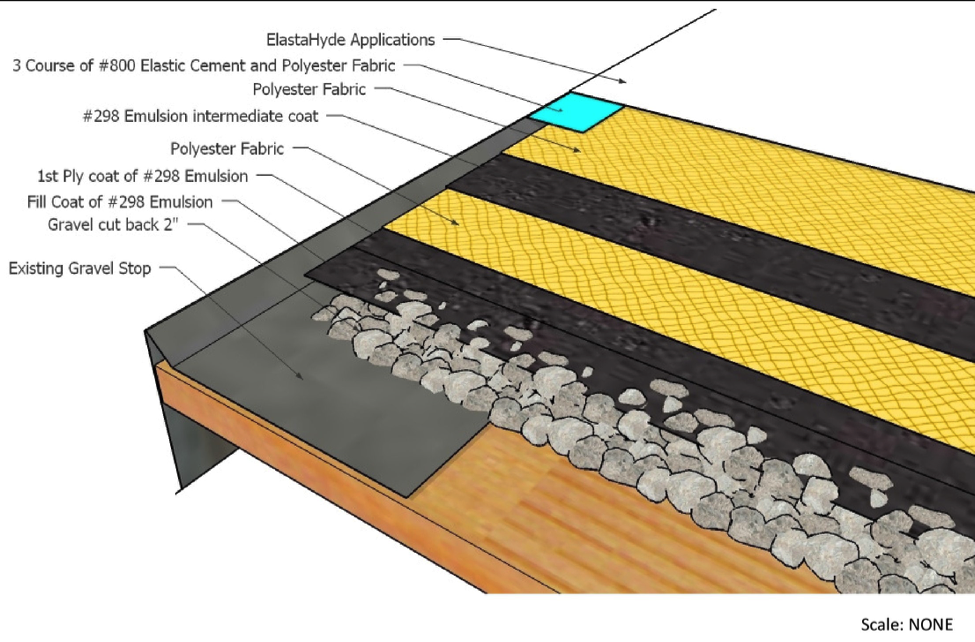

If you need to replace your gravel roof a complete tear off and replacement of the entire roofing system can be an expensive option. A more cost effective option might be to restore the entire roof using a Fluid Applied Reinforced Roofing system. Fluid Applied Reinforced Roof systems with asphalt emulsion bases extend the life of existing gravel roofs.

This method includes the following general steps.

- Remove all loose gravel, dirt, dust & debris by vacuum and power blowing.

- Repair roof area as need. Including existing blisters, splits, pipe penetrations, terminations, flashings, drains, and scuppers.

- Apply fill coat of 298 emulsion as needed.

- Next, apply 298 asphalt emulsion with 1 ply of polyester fabric over entire roof area to build a tough flexible membrane.

- Then, apply 298 asphalt emulsion with 1 ply of polyester fabric over entire roof area to build a tough flexible membrane.

- Apply a second coat of 298 asphalt emulsion with another 1 ply of polyester fabric over entire roof area to build a tough flexible membrane.

- Top coat with Elastahyde

For project-specific advice and budget numbers, click here to contact Western Colloid.

Gravel roofs can last for decades and are a great solution for buildings across the country. For more information on how to maintain your gravel roof for a long time to come, visit the Western Colloid website.