PROJECT PROFILE – High Rises!

The thrill, the danger, the view!

Re-roofing a high rise takes a particular set of skills. Getting the contractors their roofing products takes another.

Whether it’s the painstaking work of bucket by bucket up a freight elevator or coordinating with a crane in the middle of the night Western Colloid, with their 50-year history, has supplied them all.

As we are currently suppling our #720 Elastahyde to a 27-story tall building with a world class view. We thought we would revisit a few of our more memorable projects from the past.

If you follow our social or email posts you might remember this 15-story roof in Irvine, California where the tenants or traffic could not be disturbed. A midnight crane delivery became the preferred method, weekends only! Western Colloid supplied the coating in totes half full to lessen the weight of the materials and staging of materials was kept on the perimeter of the building. The process of the crane set up, delivery and removal of materials, required pin-point accuracy. We were proud of our part in the smooth logistics for this project.

Another recent project was a 10-story High Rise in downtown Denver.

With the benefit of a freight elevator the contractor was able to work on the roof with a spray rig using materials in 55-gallon drums.

With its multiple substrates, multiple roof elevations, and multiple change orders, this job was a real challenge and a complete work in process, literally.

It was necessary to create different roof system specifications for different areas of the roof as many parts of the roof were being transformed to high traffic areas.

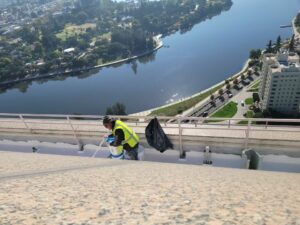

Does a steeple count as a high rise?

When it came time to re-roof this historic church bell tower and steeple there were many obstacles to overcome.

The 5 main challenges were: Working with such a small area, roofing an area that was nearly impossible to flash correctly, logistics of supplying products to such an extreme heights, very difficult access, tear-off not possible.

Western Colloid ideally covered the old substrate and encapsulated any possible hazardous waste, avoiding the tear-off. The FARR System that the contractor selected could successfully flash all of those difficult corner, angle and hard to reach areas as it was designed to cure into a single monolithic membrane. Lastly, the challenge of getting the products up on the roof was solved with a strategically placed hose that pumped the product directly up to the bell tower.

It is important to note due to the challenges of removing an existing roof that complete tear-offs pose a real problem with high rises. How to handle the debris that is removed and at what cost? That is another important benefit with Western Colloid’s roof restoration solutions. We can provide a warrantied roof over the old one!

We are happy to say all the contractors were pleased with the flexibility our products allowed along with the continued support of our field and logistics team. That is two of the most important benefits of working with Western Colloid, flexibly and support. Let’s not forget the great coating systems. Please contact us today for your next high-rise challenge.

- Lightroom

- Lightroom

- Totes being delivered